Customizable Packaging Stainless Steel 3-Stage 1200ml Capacity Dynamic Balance Technology Hotel Smart Food Processors 0.75Hp

Other recommendations

Customization

Function

Min. order: 1

Overview

Product Paramenters

|

Technical Specification

|

||||||||||

|

Model

|

FCA-726C/Y

|

Grinding system

|

3-Stage Grind

|

Swivel Impellers

|

2Cr13

|

|||||

|

Color

|

Gray

|

Switch

|

Built-In Air Switch

|

Truntable

|

SS

|

|||||

|

Disposer Feed

|

Continuous Feed

|

Auto-Reverse Grind System

|

NO

|

Hopper

|

PP+GF30%

|

|||||

|

Motor HP (HP)

|

3/4Hp 560w

|

Timer

|

NO

|

Grind Chamber

|

Aluminum alloy

|

|||||

|

Voltage (Volts)

|

220~240v

|

Motor Protection

|

Overload and over temperature

|

Bearing

|

Ball bearing

|

|||||

|

Frequency

|

50Hz

|

Drainage system

|

2 Star Grade

|

Warranty

|

3 years for the whole unit

|

|||||

|

Motor Type

|

AC Motor

|

Sink Flange

|

SS

|

Life text

|

10 years

|

|||||

|

No Load RPM

|

1450

|

Stopper

|

SS

|

Product Dimension(mm)

|

200*200*350

|

|||||

|

Load RPM

|

1200

|

Splash Guard

|

Removable

|

Package Dimension (mm)

|

275*275*415

|

|||||

|

Grinding Capacity

|

1200

|

Waste Elbow

|

PP

|

N.W

|

8.4kg

|

|||||

|

Noise

|

52dB

|

Grind Ring

|

SS

|

G.W

|

8.9kg

|

|||||

Products Description

Auto-Reverse Grind(Wireless switch only)

Traditional garbage processors typically use unidirectional rotation grinding to dispose of garbage. While this method can process most of the garbage, it may encounter difficulties when dealing with hard waste.The intelligent reversible technology solves this problem perfectly. This technology enables the garbage processor to grind alternately in both directions, thereby more fully breaking down various types of waste.

2-stage Grinding system

The third generation multi-stage grinding cutter can process more complex food waste and make the residue finer to avoid clogging the sewer.

3-bolt SS flange

The three-point snap flange made of stainless steel allows for faster installation and more secure.

Turbo drain

The grinding disc is equipped with a spiral scouring design, which can create a fast rotating water flow and generate strong scouring force to clean the pipeline and prevent blockage, making the sewer more unobstructed.

Antibacterial grinding chamber

The cavity is made of antibacterial resin, which has been tested by a professional organization and has an antibacterial rate of over 99.9%.

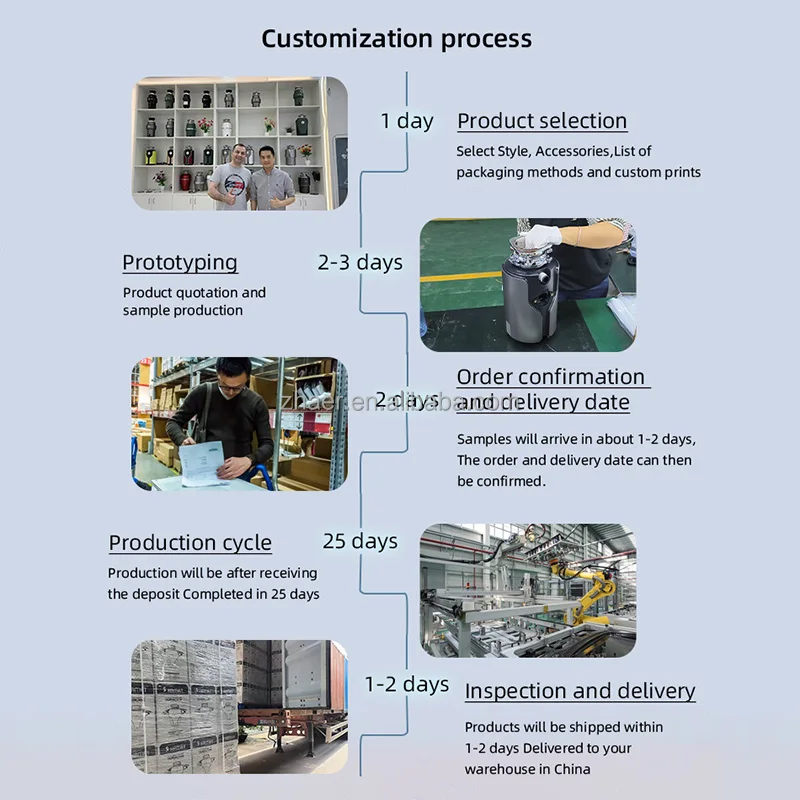

Customization details

Certifications

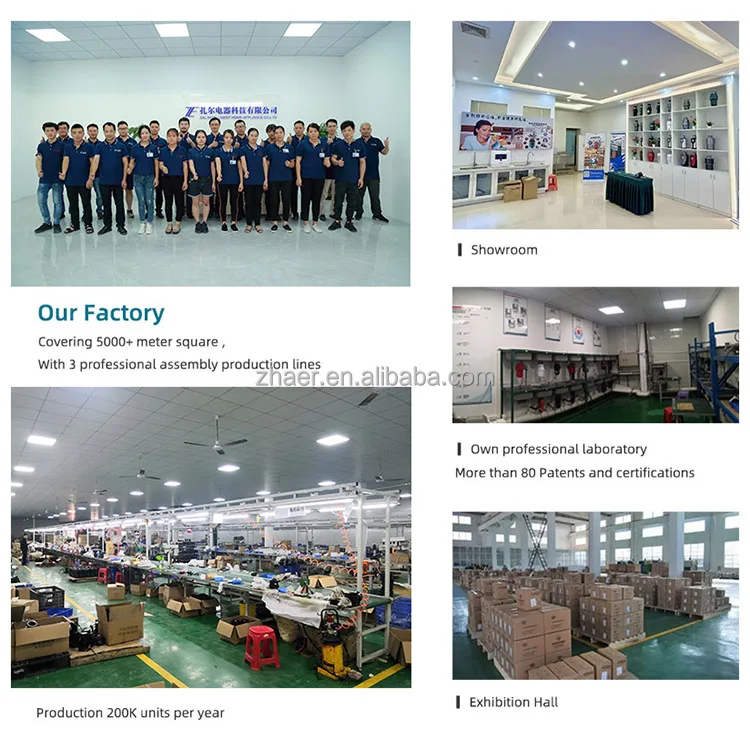

Our Company

Exhibition

FAQ

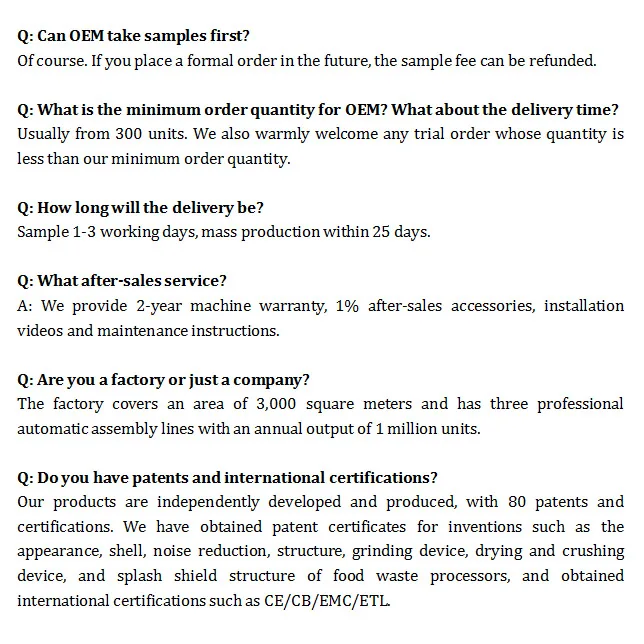

Can OEM take samples first?

Of course. If you place a formal order in the future, the sample fee can be refunded.

What is the minimum order quantity for OEM? What about the delivery time?

Usually from 300 units. We also warmly welcome any trial order whose quantity is less than our minimum order quantity.

How long will the delivery be?

Sample 1-3 working days, mass production within 25 days.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

What after-sales service?

We provide 2-year machine warranty, 1% after-sales accessories, installation videos and maintenance instructions.

Are you a factory or just a company?

Our factory covers an area of 3,000 square meters and has three professional automatic assembly lines with an annual output of 1 million units.

Do you have patents and international certifications?

Our products are independently developed and produced, with 80 patents and certifications. We have obtained patent certificates for inventions such as the appearance, shell, noise reduction, structure, grinding device, drying and crushing device, and splash shield structure of food waste processors, and obtained international certifications such as CE/CB/EMC/ETL.

- Tel:

-

Email:

INQUIRY

Certifications

SUBSCRIBE

INQUIRY